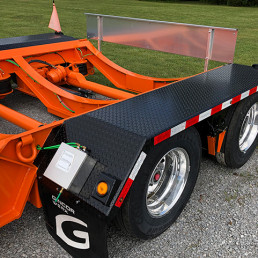

Tag Trailer

TAG TRAILERS

| Standard Features |

|---|

| LED Standard Lighting Package Grote™ Blue Seal Harness |

| Inner and outer white steel powder coated wheels |

| Cooper 235/75R17.5 RM170 |

| Logo mud flaps at rear |

| Holland Mark V Landing Gear |

| Unimount hubs and drums with long studs |

| 6 pair D-Rings for full deck length tie down |

| Continental, Bridgestone, Michelin, Toyo, Kumho |

| Meritor WABCO ABS System |

| JC HD 3 leaf spring suspension |

| Lockable tool box in tongue |

| Options |

|---|

| Aluminum wheels |

| Hendrickson Air Ride Suspension |

| 3 Axle, 4 Axle Lift, Steer |

| Back-up alarm & strobe light(s) |

| Aluminum Tool Box |

| 3 Axle, 4 Axle Lift, Steer |

| Broom, Safety Cone, Flag Holders |

| Air assist rear ramps |

| PINTLE EYE TYPE |

|---|

| Holland 4 bolt |

| DECK DIMENSIONS |

|---|

| 22’ Main deck length, 6’ Beavertail |

| OVERALL WIDTH |

|---|

| 8’6” Overall (no rub rail) |

| MAIN RAILS |

|---|

| 12” x “I” Beam T-100,000 Yeild Steel rails |

| SIDE RAIL TYPE |

|---|

| 10” C-Channel with flat to the inside |

| BEAVERTAIL |

|---|

| Wood Filled or 3/16” Checker Plate |

| FRAME COLOUR |

|---|

| Multiple options available |

| LANDING GEAR |

|---|

| Holland™ 2 Speed Leg with Gearbox on D/S 14” Travel |

| AXLE SPREAD AND CONFIGURATION |

|---|

| Fixed 49” |

| PRIMARY AXLE OPTIONS |

|---|

| Tapered Spindle |

| 16 1/2” Brake Shoes |

| Slack Adjuster-Automatic-Curved |

| PRIMARY SUSPENSION OPTIONS |

|---|

| JC HD 3-Leaf Spring with 25K Axle, 79-1/2” Track 6, 1/2” Ride Height |

| DECKING |

|---|

| 2 - 1/4” White Oak |

| D-RINGS |

|---|

| 6 Pairs |

| RAMPS @ REAR |

|---|

| Spring Assisted |

| ABS SYSTEM |

|---|

| 2S/1M Merritor™ ABS System |

| LIGHTING & ACCESSORY ELECTRICAL |

|---|

| LED Standard Lighting Package |

| ADDITIONAL OPTIONS |

|---|

| Tool Box with Aluminum Lid in Tongue Round Document Holder |

| HUBS AND DRUMS |

|---|

| Unimount with Long Studs |

| Hubs Filled with Gear Oil 80W90 |

| TIRES |

|---|

| Cooper 235/75R17.5 RM170 |

| INNER WHEELS |

|---|

| White Steel |

| OUTER WHEELS |

|---|

| White Steel |

| MUD FLAPS |

|---|

| Logo Flaps @ Rear |

Specs sheet

TAG TRAILER

TAG TRAILERS

We’ve been building trailers for 40 years. Our longevity has been fueled by our ability to meet customers demands and to foster a great work environment for our people. Our customers trust us to solve their problems and deliver a premium product.

Lorem ipsum

EXPERIENCE BREEDS QUALITY

Did you know we are certified service and refurb experts?

Lorem ipsum

Looking for a career opportunity at JC Trailers?Check out our career section and see if there is a fit for you.

Request a quote for more information

Sliding Axle Trailer

SLIDING AXLE TRAILER

| Standard Features | |

|---|---|

| Length Overall: | 48 Ft. |

| Deck Width: | 102” |

| Capacity: | 35 metric tons, main deck rating 50,000 Lbs. in 10’ |

| King Pin Set Back: | 21” |

| Coupler Height: | 49” |

| Upper Deck Height: | 60” Approximate |

| Upper Deck: | 10’ Length X 102” Width, 1 5/16” Apitong Decking |

| Lower Deck: | 38’ X 102” X 37” Height With 1 5/16” Apitong Decking. Front of deck lifts on 2-5” hydraulic cylinders at 2000 min to 3000 max psi to level with upper deck. Approach angle when lifted is approximately 6 ½-8 degrees. |

| CONSTRUCTION |

|---|

| Main beams fabricated in house of T-1 100,000 yield plate 16” main beams. Crossmembers are 3” I-beam. All side rails fabricated T-1 upper deck is T-1 and HSLA plate fabricated main beams, 12” depth with 8” channel crossmembers and 10” deep outside rail. |

| SECUREMENT |

|---|

| Deck comes with chain keyhole slots every 2’. |

| FIFTH WHEEL PLATE |

|---|

| 3/8” HSLA plate with 2” Holland SAE pin. |

| JACK |

|---|

| 1pr. Holland mark v 2-speed, heavy duty. |

| SUSPENSION |

|---|

| 3 – Hendrickson HT250 series underslung 6.5” Ride height, 60” x 60”x 60” C/W dump valve & load gauge. |

| AXLES |

|---|

| 3 - 23,000lb. X 77 ½” |

| AXLE MOTION |

|---|

| Axles move on 4, 6” diameter rollers, powered by two 4” hydraulic cylinders. Sliding axle speed is controlled by output of truck hydraulic fluid and is measured is gallons per minute |

| HUBS |

|---|

| 15” – 8 bolt piloted. |

| BRAKES |

|---|

| 12.25 X 7.5 C/W 30/30 Maxis; auto slacks & dust shields. |

| TIRES |

|---|

| 12 – 235/75r17.5 Cooper Tires |

| WHEELS |

|---|

| 12-steel 8 bolt 6.75 X 17.5. |

| ABS |

|---|

| 2SIM Haldex |

| STORAGE |

|---|

| 2 – aluminum box 12” x 24” x 36” upper deck each side. |

| WINCH |

|---|

| 2 speed 30,000 lbs. Warn winch, 245 feet of 5/8 cable. |

| PAINT PROCESS |

|---|

| Mechanical clean, commercial sandblast, 2-part epoxy primer, polyurethane finish. |

| COLOUR OPTIONS |

|---|

| John Deer Yellow |

| Cardinal Red |

| Omaha Orange |

| Black |

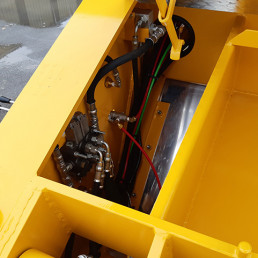

| HYDRAULICS |

|---|

| Wet line connection at front rail for tractor connection. |

| HYD. CONTROL |

|---|

| Manual control roadside of goose neck remote control comes with, winch control, deck tilt, sliding axle |

| ELECTRICAL |

|---|

| 7-wire cable harness C/W 7 pin plug. Junction box front of trailer. |

| LIGHTS |

|---|

| LED strobe lights rear facing deck work lights stop, turn and running lights side marker lights |

| CONSPICUITY TAPE |

|---|

| All round to D.O.T. Standards. |

| MUD FLAPS |

|---|

| 1pr. behind fixed tridem |

| DOCUMENTS |

|---|

| 1-holder mounted in front of goose neck. |

Specs sheet

SLIDING AXLE TRAILER

SLIDING AXLE TRAILER

We’ve been building trailers for 40 years. Our longevity has been fueled by our ability to meet customers demands and to foster a great work environment for our people. Our customers trust us to solve their problems and deliver a premium product.

Lorem ipsum

EXPERIENCE BREEDS QUALITY

Did you know we are certified service and refurb experts?

Lorem ipsum

Looking for a career opportunity at JC Trailers?Check out our career section and see if there is a fit for you.

Request a quote for more information

Extendable Step Deck Tanker Trailer

EXTENDABLE STEP DECK

TANKER TRAILER

| Standard Features | |

|---|---|

| Capacity: | 35 Ton |

| Overall Length: | Collapsed 57’2” Extended 77’2” |

| Overall Width: | 8’6” to 12’-0” |

| Deck Length: | Closed 33’6” Extended 57’6” |

| Deck Height: | 26” |

| Saddle Height: | 16” with 8” Ground Clearance |

| Upper Deck Height: | 60” with 49” Coupler height |

| LED Standard Lighting Package Sealco™ | |

| Inner and outer white steel powder coated wheels | |

| 245/70R17.5 Tires | |

| Options |

|---|

| Aluminum wheels |

| Pin On Axle ( Flip up ) |

| Unimount hubs and drums with long studs |

| Back-up alarm & strobe light(s) |

| Up to 90 ft Extendable Applications |

| Dexter™ 25,000 lbs Axles Dropped |

| Wireless Axle Load Weight System |

| Logo mud flaps at rear |

| FRAME |

|---|

| Main chassis +/-beams fabricated in house of T-1 100,000 yield steel “I” beams |

| Upper Deck 10’ with 6” perimeter frame on 4” ch crossmembers. Rub-rail & pockets on 2’ centers. |

| Lower deck outer frame 18” tubular steel, 55” chassis width. |

| 16” “I” beam pullout section. Fixed section will be open center with eight 10” preformed 3/16” crossmembers recessed 3” |

| Both sides of fixed section comes with rub rail and pockets |

| Rear bumper also formed down to accommodate tank load |

| EXTENSION |

|---|

| Pull out style, air activated locking pins (every 3 ft.) and steel rollers |

| TIE DOWNS |

|---|

| 1 pair located rear of G/N both sides |

| 1 pair in center of bolsters of rear bridge |

| 1 pair on side of outter top flange of pull out section |

| FLAG HOLDERS |

|---|

| 1 pair located rear corners of rear fenders. |

| WIDE LOAD |

|---|

| Pair of pockets rear of bridge C/W fold down “D” sign. |

| A.B.S. |

|---|

| Wabco 4S2M system with roll stability |

| AIR SUSPENSION |

|---|

| 3 Hendrickson 25,000 # x 6.5” R/H C/W stainless steel load gauge & dump located roadside centre bolster. Manual lever for various heights, located roadside center bolster. |

| AXLES |

|---|

| 25,000Lb. x 79 ½” track x 5” round, tapered spindles & bearings |

| HUBS |

|---|

| 10 bolt hub piloted oil bath with sight caps & metric long studs. |

| BRAKES |

|---|

| 16.5 ” x 7” air, Haldex auto slacks, 30/30 maxi chambers, cast OB drums and dust covers, |

| WHEELS |

|---|

| 10 bolt 8.25 x 22.5 steel white. |

| TIRES |

|---|

| 245/70R J 17.5 Continental HSR2SA 18 ply. |

| EMERGENCY LIGHTING |

|---|

| 2 Pair, Amber flashing lights at front of tandem. 2 4-Pin sockets located rear of trailer for magnetic strobes |

| STORAGE |

|---|

| Front of G/N and rear of G/N with steel hinged door. |

| DOCUMENTS |

|---|

| Holder mounted roadside front of G/N. |

| PAINT |

|---|

| Standard colors, commercial sandblast, 2 part epoxy primer, polyurethane finish coat, |

| CONSPICUITY TAPE |

|---|

| To D.O.T Standards red/silver |

| MUD FLAPS |

|---|

| 1 pair located on rear of last axle |

| ELECTRICAL / LIGHTING |

|---|

| 7 Wire sealed cable harness c/w 7 pin receptacle |

| All lighting to D.O.T. Standards |

Specs sheet

EXTENDABLE STEP DECK TANKER TRAILER

EXTENDABLE STEP DECK TANKER TRAILER

We’ve been building trailers for 40 years. Our longevity has been fueled by our ability to meet customers demands and to foster a great work environment for our people. Our customers trust us to solve their problems and deliver a premium product.

Lorem ipsum

EXPERIENCE BREEDS QUALITY

Did you know we are certified service and refurb experts?

Lorem ipsum

Looking for a career opportunity at JC Trailers?Check out our career section and see if there is a fit for you.

Request a quote for more information

35 Ton Tandem Float Trailer

35 TON TANDEM

FLOAT TRAILER

| Standard Features | |

|---|---|

| Capacity: | 35 Ton |

| Overall Length: | 40’-53’ |

| Overall Width: | 8’-6” |

| Length: | 22’-35’ |

| Deck Height: | Approx. 34” |

| Tire Weight: | 12,500 Kg (2 Axle) |

| Bridge Length: | 15’ |

| Rear Height: | Approx 43” Over Wheels. |

| Tie Downs: | 11 “D” Rings on each side of trailer |

| LED Standard Lighting Package Sealco™ | |

| Inner and outer white steel powder coated wheels | |

| 255/70R22.5 Tires | |

| Logo mud flaps at rear | |

| Unimount hubs and drums with long studs | |

| Dexter™ 25,000 lbs Axles | |

| Options |

|---|

| Aluminum wheels |

| Rear bridge with extra axle |

| Rear Ramps for Rear Deck |

| Back-up alarm & strobe light(s) |

| Jeep options |

| Platform on G/N |

| Flip up Extendable G/N |

| Drop sides |

| FRAME |

|---|

| Main chassis +/-beams fabricated in house of T-1 100,000 yield steel 12” depth “I” beams |

| All Crossmembers are 10” wide flange on 20” centers through main chassis beams. |

| Outside rails 9” depth reinforced “I” beams fabricated in house of T-1 100,000 yield steel. |

| Deck covered in 2 ¼” oak secured with clips & plated bolts |

| Full depth walk-through plated boomwell closed at rear. |

| Center front of B/W formed down over 1st axle with 10” x 1” flat bar ramped down to rear of centre deck. |

| OUTRIGGERS |

|---|

| 13 per side in rails C/W 2-12’ outrigger boards. |

| TIE DOWNS |

|---|

| 12 “D” rings located each side of trailer in rail. |

| 1 pair in each bolster & rear corners of bridge. |

| 1 pair rear of goose neck flange. |

| FLAG HOLDERS |

|---|

| 1 pair located rear corners of bridge complete with flags. |

| WIDE LOAD |

|---|

| Pair of pockets rear of bridge C/W fold down “D” sign. |

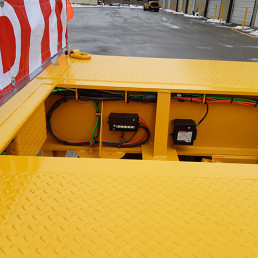

| STORAGE |

|---|

| 1 rear of G/N with chain bar & aluminum lockable lid. |

| 1 front centre of deck drainage bottom & lockable lid. |

| PRIMARY SUSPENSION |

|---|

| 2 Air ride 25,000 # x 9” R/H C/W stainless steel load gauge & dump located roadside centre bolster. Manual lever for various heights, located roadside center bolster. |

| AXLES |

|---|

| 2 25,000Lb. x 75 ½” track x 5” round, tapered spindles & bearings |

| HUBS |

|---|

| 10 bolt hub piloted oil bath with sight caps & metric long studs. |

| BRAKES |

|---|

| 16.5 ” x 7” air, Haldex auto slacks, 30/30 maxi chambers, cast OB drums and dust covers, plus IMT 25 Gold Cam Encl. |

| WHEELS |

|---|

| 10 bolt 8.25 x 22.5 steel white. |

| TIRES |

|---|

| 275/70R J 22.5 Continental HSR2SA 18 ply. |

| EMERGENCY LIGHTING |

|---|

| 2 Pair, Amber flashing lights at rear of tridem, self-charging battery pack & switch for operation when running on highway or when G/N is detached for loading. |

| CMVSS/FMVSS approved sealed LED lights, rubber grommet mounted. |

| Stop/Turn/Tail lights @ each side |

| Marker Lights and Mid-turn signals for various deck heights |

| DOCUMENTS |

|---|

| Holder mounted roadside front of G/N |

| PAINT |

|---|

| Standard Colors, Commercial Sandblast, 2 part epoxy primer, polyurethane finish coat. |

| CONSPICUITY TAPE |

|---|

| To D.O.T Standards Red / Silver |

| MUD FLAPS |

|---|

| 1 pair located on rear of last axle |

| ELECTRICAL / LIGHTING |

|---|

| 7 Wire sealed cable harness c/w 7 pin receptacle All lighting to D.O.T. Standards |

Specs sheet

35 TON TANDEM FLOAT TRAILER

35 TON TANDEM FLOAT TRAILER

We’ve been building trailers for 40 years. Our longevity has been fueled by our ability to meet customers demands and to foster a great work environment for our people. Our customers trust us to solve their problems and deliver a premium product.

Lorem ipsum

EXPERIENCE BREEDS QUALITY

Did you know we are certified service and refurb experts?

Lorem ipsum

Looking for a career opportunity at JC Trailers?Check out our career section and see if there is a fit for you.

Request a quote for more information

Tridem Axle Hydraulic Tilt Drop Deck Trailer

TRIDEM AXLE HYDRAULICTILT DROP DECK TRAILER

| Features | |

|---|---|

| Tare Weight: | 10,700 KG Approx. |

| Overall Length: | 53’ |

| Overall Width: | 102” |

| DECK HEIGHT |

|---|

| Front (with 48” coupler) 60 |

| Rear (full air) approx. 36” |

| Rear (full air) approx. 36” |

| UPPER DECK |

|---|

| O11’-0” length x 102”” width, 1-5/16” Apitong shiplap decking. |

| LOWER DECK |

|---|

| 33’ x 102” x 36” height with 2 ¼” oak decking. Front of deck lifts on two 6” hydraulic cylinders to level with upper deck. |

| BEAVERTAIL |

|---|

| 8’ length x 102” width c/w 5’ x 40” wide air ramps all wood decking with tapered steel tips to lay approx flush with ground when deck tilted up. Note: air ramps are 2 ¼” oak covered with tapered steel tip & operate with one air bag. Hyd. dampening cylinder & ball valve air control in rail at front of b/t. |

| CONSTRUCTION |

|---|

| Main beams fabricated in house of t-1 100,000 yield flanges & web 22” depth to 13” over axles. Crossmembers are 6” I-beams first 8’, balance 6” channel. All side rails fabricated T-1 10” I-beams. Upper deck is T-1 and HLSA plate fabricated main beams, 12” depth with 4” channel crossmembers and 8” channel outside rail [ legs in] with rub rail & pockets. |

| BOOM REST |

|---|

| Rienforced ½” steel plate welded to main chassis beams Centre rear of deck just ahead of beavber tail. |

| FIFTH WHEEL PLATE |

|---|

| 3/8” HSLA plate rienforced with 6” & 4” st’d channel & 2” Holland SAE pin with 18” setback. |

| FIFTH WHEEL PLATE |

|---|

| 3/8” HSLA plate rienforced with 6” & 4” st’d channel & 2” Holland SAE pin with 18” setback. |

| JACK |

|---|

| 1pr. Holland mark v 2-speed rectangular foot. |

| SUSPENSION |

|---|

| 3 – Hendrikson 25,000 # 6.5” Underslung c/w dump valve & load gauge in stainless steel control box under deck roadside for manual or cab control of forward lift axle. |

| AXLES |

|---|

| 3 – Dexter 22,500# x 5” rd. X 79 ½”” 72” / 72” spread Note: front axle lifts with hendrikson lift kit. |

| HUBS |

|---|

| Eight bolt piloted, tapered spindles & bearings oil bath & sight covers |

| BRAKES |

|---|

| 12.25 X 7.5 c/w 30/30 maxis, Haldex auto slacks, enclosed cams, outboard drums & dust shields. |

| TIRES |

|---|

| 12– Continental HTL-2 Eco Plus 245/70R 17.5. |

| WHEELS |

|---|

| 12- eight bolt 6.75 X 17.5 Alcoa aluminum st’d polish. |

| ABS |

|---|

| 2 sim Haldex on tridem. |

| SECUREMENT |

|---|

| Heavy duty 3/8” x 3” rub rail with ¼” st’d stake pockets on 2 ft. centres on upper deck outside rails. Lower deck & b/t has “D” rings on approx 2 ft. centres on outside rails front thru beaver tail. |

| STORAGE |

|---|

| 2- aluminum boxes 18`x 24`x36`` under deck one each side. |

| WINCH |

|---|

| No winch but diverter valve & hyd lines installed with Steel mounting plate for customers future winch. |

| PAINT |

|---|

| Mechanical clean, commercial sandblast, 2-part epoxy primer, standard paint colours available. |

| HYDRAULICS 3 |

|---|

| – Wet line quick connectors at front rail for tractor connection. Controls for tilt deck rear road side of gooseneck. |

| POWER PACK |

|---|

| optional extra |

| ELECTRICAL |

|---|

| 7-wire sealed cable harness c/w 7 pin plug. 3-Large lights each side rear, 3 small clearance lights centre rear, 2-small clearance lights front rail, 2pr. small clearance lights in side rails, 1 pr. directional markers centre of rail both sides. All lights L.E.D. |

| BACK UP ALARM |

|---|

| Wired with 1-pr. clear led lights for reverse operation wired to centre pin. |

| STROBES |

|---|

| 1-pr. 4” rd amber in ramps with switch. |

| WIDE LOAD |

|---|

| 2- each side of deck 12’ flip out red. [ 1-front / 1- rear.] |

| CONSPICUITY TAPE |

|---|

| All round to D.O.T. Standards. |

| MUD FLAPS |

|---|

| 1pr. behind fixed tridem. |

| DOCUMENTS |

|---|

| 1- holder mounted in front rail road side. |

Specs sheet

TRIDEM AXLE HYDRAULIC TILT DROP DECK TRAILER

TRIDEM AXLE HYDRAULICTILT DROP DECK TRAILER

We’ve been building trailers for 40 years. Our longevity has been fueled by our ability to meet customers demands and to foster a great work environment for our people. Our customers trust us to solve their problems and deliver a premium product.

Lorem ipsum

EXPERIENCE BREEDS QUALITY

Did you know we are certified service and refurb experts?